On February 8, 2024, Prof. Huang Xiaoxu's team at CQU's College of Materials Science and Engineering, in collaboration with Prof. Matthew S. Dargusch's team at the University of Queensland, Australia, published a paper of research significance in Science entitled "Ultra-uniform, strong, and ductile 3D printed titanium alloy through bifunctional alloy design." Previously, CQU has published six papers on materials science in Science and Nature.

Paper displayed on the webpage

3D printed (additive manufacturing) metal materials usually feature coarse columnar crystals and unevenly distributed formation phases. Such a structure not only leads to heterogeneity in the mechanical properties of the components, but also reduces the mechanical properties of the components. For commonly used metallic materials (e.g., substable β-titanium alloys, heat-treatable aluminum alloys, and nickel-based high-temperature alloys), the coexistence of columnar crystals and heterogeneously distributed phases in their 3D-printed components is often observed, which poses a tough challenge for obtaining consistent and superior mechanical properties.

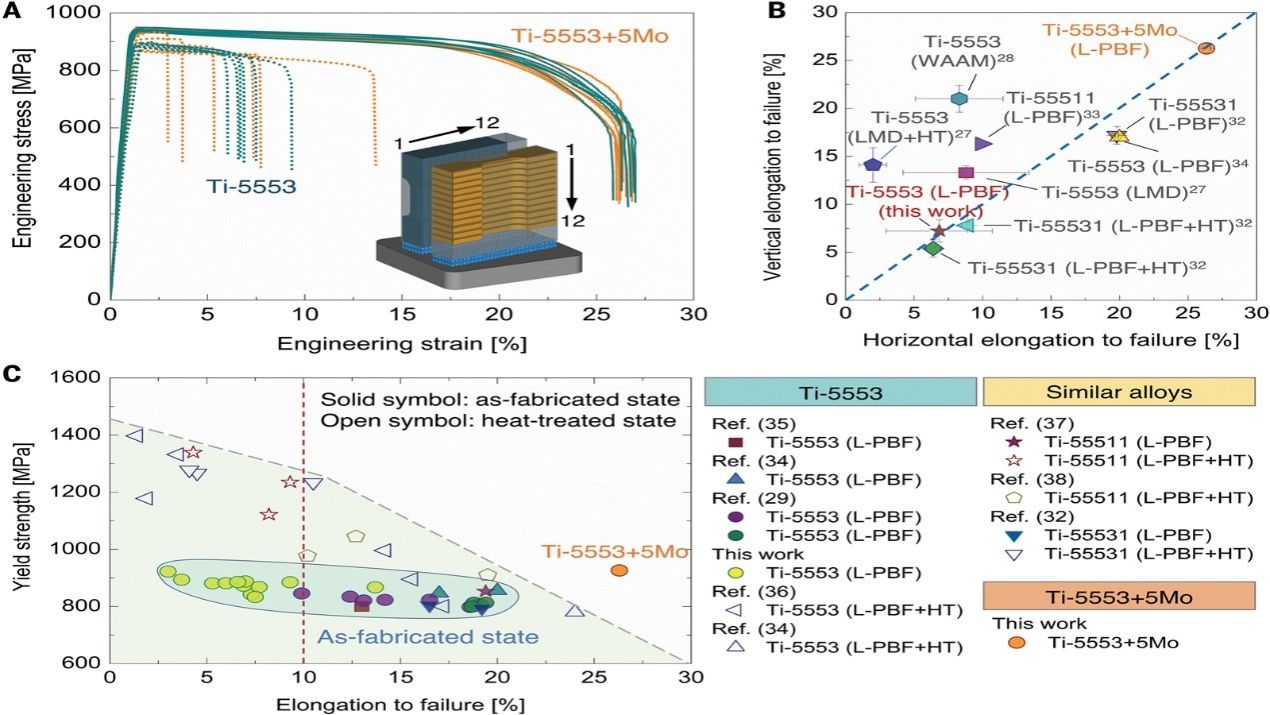

To address the aforementioned challenge, the research team proposed a "two-for-one" alloy design strategy. The use of Ti-5Al-5Mo-5V-3Cr (Ti-5553 for short) as a model alloy and the addition of molybdenum (Mo) nanoparticles achieved the dual functionality of a single additive. Specifically, (1) during solidification, the incompletely dissolved molybdenum particles address the columnar crystal grain structure through grain refinement; (2) during solid-state phase transformation, the dissolved molybdenum inhibits the precipitation of the undesirable phases. The microstructural changes induced by this bifunctional addition not only contribute to the highly uniform mechanical properties of the model alloys, but also improve the strength and plasticity of the model alloys at the same time. This study demonstrates how a single addition can address the unfavorable microstructures of 3D printed metallic materials, providing a pathway to achieve desirable mechanical properties of alloys directly from 3D printing.

Addition of Mo nanoparticles significantly improves the mechanical properties of 3D printed Ti-5553 alloy and its homogeneity

Link of the paper: https://www.science.org/doi/10.1126/science.adj0141