Advanced Materials published a research paper of the research group led by Professor Hu Chenguo of the School of Physics, Chongqing University recently. The title of the research paper is An Ultrarobust and High-Performance Rotational Hydrodynamic Triboelectric Nanogenerator Enabled by Automatic Mode Switch and Charge Excitation. Chongqing University is the first author of the paper. Fu Shaoke and He Wencong, doctoral candidates of Chongqing University, are the first co-authors. Professor Hu Chenguo of CQU and Professor Liu Hong of Shandong University are corresponding co-authors of the paper.

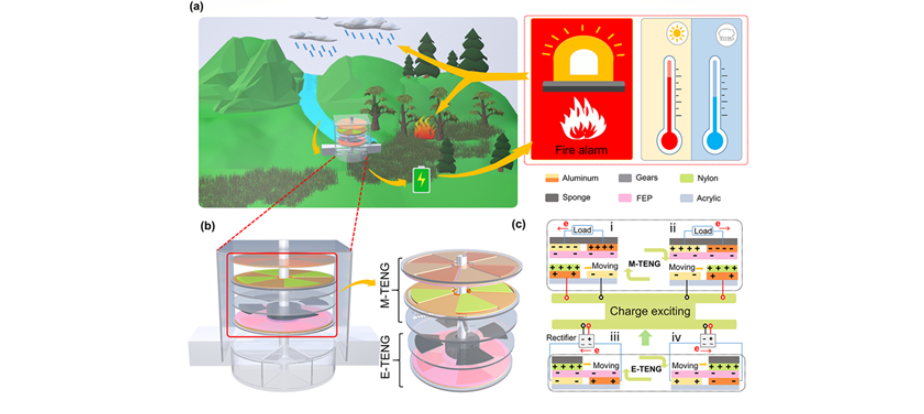

The pictures above show the application, structural diagram and working principle of CEMA-TENG. a) The application of CEMA-TENG to water flow energy collection and intelligent forest monitoring. b) The structural diagram of CEMA-TENG. It consists of two parts: the upper part is the generator and the lower part is the water turbine. The water turbine is designed to collect the water flow from the mountain and provide power for the rotation of CEMA-TENG. c) Working principle of externally-excited CEMA-TENG in one operation cycle.

The foundation and core of the rapid development of big data and Internet of Things are hundreds of millions of sensor networks. However, the exclusive reliance on the existing battery energy supply mode entails problems such as sustainable energy supply and difficult maintenance. Therefore, the development of self-energy-supply technology based on environmental energy recovery will be of great significance for the development of the sensing part of the Internet of Things. Triboelectric nanogenerator has been proved to be an effective way to provide self-energy supply of sensor parts by using environmental mechanical energy, and boasts fantastic potential applications.

When TENG is practically applied to capture environmental mechanical energy, its electrical output performance is an important problem we are concerned of, and its surface charge density is the most important parameter needed to determine the output performance of TENG. In addition, the heat generated by sliding friction in the medium and high-frequency region and the excessive wear on the material surface seriously reduce the electrical output performance of TENG. At present, researchers have proposed various effective methods to improve surface charge density and reduce mechanical wear. However, the improvement of electrical output performance and durability still poses a challenge in rotating and sliding TENG. Therefore, it will be of great significance to further explore the optimal design to improve both the durability and electrical output performance.

Researchers in this Project managed to effectively improve the electrical output performance of TENG by means of charge excitation. Compared with ordinary sliding TENG, the electrical output performance was improved by 2.6 times. With smart design of centrifugal force driving layer and gear system, the automatic contact-separation of main TENG(M-TENG) working mode and the speed adjustment of excitation TENG (E-TENG) were realized, which effectively reduced the sliding friction loss of TENG in medium and high-frequency region and improved the working durability of TENG. After 72,000 cycles of continuous operation, 94% of the electrical output performance was maintained, while the electrical output performance of the ordinary rotary sliding TENG was reduced to 30%. The researchers also managed to effectively improve the electrical output performance and durability of TENG, and successfully converted the mechanical energy of water flow into electrical energy to supply power for a variety of commercial devices through water turbine design, provided an ideal solution to the self-powered monitoring power supply of intelligent forest environment, and expanded the application of Internet of Things self-powered system in remote areas.

Link of the paper: https://doi.org/10.1002/adma.202105882